How To Make Your Own XLR Cables

Nail The Mix Staff

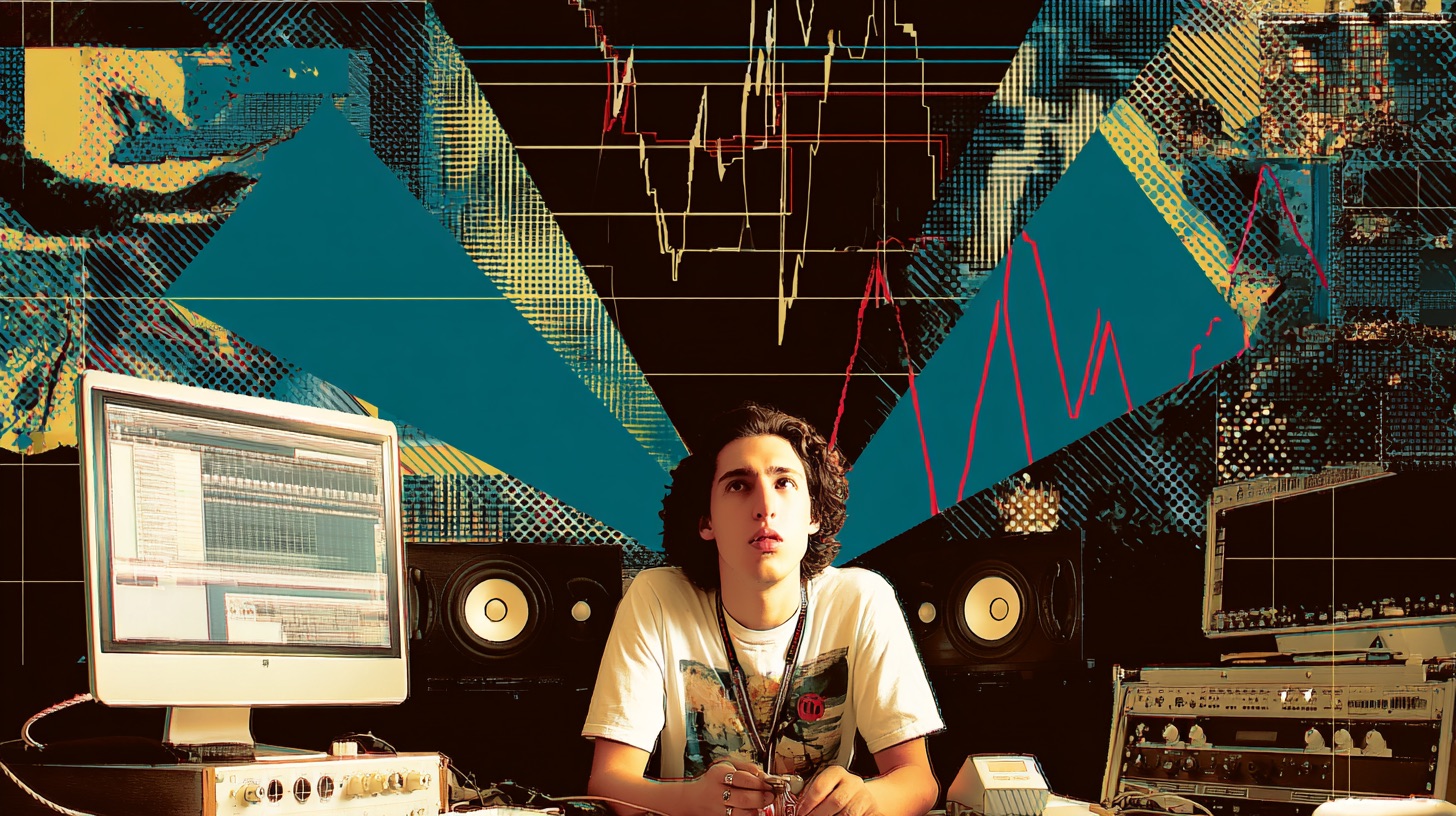

Ever find yourself short an XLR cable at the worst possible moment? Or maybe you’re tired of shelling out cash for pre-made ones, never quite sure of the quality inside? Well, Dave Otero (the mastermind producer at Flatline Audio, known for his work with bands like Cattle Decapitation, Archspire, and Khemmis) dropped some serious knowledge on making your own, and it’s easier than you might think. Building your own cables isn’t just about saving a few bucks; it’s about control, choosing your components, and that sweet satisfaction of knowing you made it yourself. Plus, it’s a killer skill for any audio engineer or musician.

Let’s dive into how you can “mix” up your own pro-quality XLR cables.

Gear Up: Tools & Materials You’ll Need

Before you start melting metal, let’s get your workstation prepped. Dave lays out a pretty straightforward toolkit:

The Heat Source: Soldering Station

You’ll need a soldering iron. Dave uses a station with adjustable temperature, warming it up to around 350°C and then cranking it to a solid 450°C (that’s about 850°F!) for the actual soldering. If you don’t have a fancy station, those single-heat units that plug straight into the wall can work too. Just be mindful that it’s seriously hot!

Essential Hand Tools

- Helping Hands: This little jig with clips is super useful for holding wires and connectors steady. Dave admits his is a bit flimsy and recommends getting a heavier, more stable one. A pro tip from him: a few rubber bands around the base can help stop it from skidding.

- Solder: The magic stuff that makes the connection. Standard rosin-core solder for electronics is what you need.

- Wire Snips/Strippers: A good pair of wire snips is crucial. One with built-in small gauge wire strippers (like for 22 AWG wire) and a plier tip is a versatile MVP.

- Scissors: For cutting cable jackets or filler material.

- Optional but Handy:

- Angle pliers

- Deep needle-nose pliers

- Angle snips (for trimming tight spots)

The Cable Components

- Balanced Cable: Dave uses a pre-cut length (around 20 feet is his go-to) of Redco Lo-Z 1 balanced cable. You’ll want a quality shielded cable with two conductors.

- XLR Connectors: You’ll need one male and one female XLR connector per cable. Brands like Neutrik are industry standards for a reason, offering durability and reliable connections you can trust for demanding setups, like the classic Fredman miking technique.

- Connector Boots: These are the screw-on back parts of the XLR connector. Don’t forget these!

Prep Work: Getting Your Cable Ready for Soldering

This is where attention to detail pays off.

The Golden Rule: Boots First!

Seriously, Dave emphasizes this: slide the connector boots onto each end of your cable before you do anything else. If you solder everything up and then realize you forgot the boots, you’ll be kicking yourself as you undo all your hard work.

Stripping the Cable

- Outer Jacket: Carefully trim away about an inch of the outer rubber jacket from each end of the cable. You want to score it lightly and then pull it off, trying not to nick the shield wires underneath.

- Shield: You’ll see a copper shield, often wound around the inner conductors. Gently untwist it and gather all the strands to one side, twisting them together tightly to form a single wire. This shield is your first line of defense against noise, which is critical when you re-amp metal guitars and need the cleanest possible signal.

- Filler Material: Some cables have filler material like cotton rope or plastic strands. Snip these away, flush with the end of the outer jacket.

Prepping the Conductors

You should now have your shield wire and two insulated inner conductors.

- Identify Wires: Typically, you’ll see a red wire and then another color like blue (as in Dave’s example), white, or black. Red is almost universally used for Pin 2 (Hot).

- Strip Conductors: Using your wire strippers (Dave uses the 22-gauge slot for his Redco cable), strip off just a tiny bit of insulation from the ends of the red and blue (or other color) conductors – just a couple of millimeters is plenty. Twist the exposed copper strands tightly.

Repeat this whole stripping process for the other end of your cable.

The Art of Tinning: Priming Your Wires and Connectors

“Tinning” means coating the exposed wire ends and the solder cups on your connectors with a thin layer of solder. This makes the final soldering process much smoother and creates stronger joints.

Tinning the Wires

With your soldering iron at full temperature (450°C), it’s time to tin.

- The Technique: Get a tiny bit of solder on the tip of your iron (this helps transfer heat). Touch the hot tip to the stripped wire end. Once the wire itself is hot enough, touch the solder to the wire, not the iron. The wire should heat the solder, causing it to flow and “soak into” the strands. You’ll see it happen – it’s pretty neat.

- Do this for the shield, red, and blue wires on both ends of your cable.

Pre-filling the Connector Pins (Solder Cups)

Now for the XLR connector inserts (the part with the pins).

- The Technique: Similar to tinning wires, get a tiny bit of solder on your iron’s tip. Touch the tip to the inside of one of the small metal cups (receptacles) where the wires will go. Once the cup is hot, feed solder directly into the cup until it’s nicely filled.

- Do this for all three pins on both the male and female connector inserts. Be careful, these little parts get hot fast!

Making the Connection: Soldering Wires to XLR Pins

This is where your cable truly comes to life.

Understanding XLR Pinout (It’s Standard!)

For balanced audio, the XLR pinout is crucial and universal:

- Pin 1: Shield (Ground)

- Pin 2: Hot (Positive – your Red wire)

- Pin 3: Cold (Negative – your Blue/White/Black wire)

Getting this wiring correct is non-negotiable, as correct polarity is the foundation for a cohesive sound, especially when you need to phase-align a miked signal with a DI. Most XLR connectors have tiny numbers molded next to each pin. Double-check them! Dave mentions he likes to keep his male connector on the right and female on the left when working, which helps him remember that Pin 2 (Red) is always on the “outside” terminal for his workflow. Find a system that works for you.

The Soldering Process

- Plan Your Attack: Dave often starts with the red wire to Pin 2. You might want to gently bend your tinned wire ends to aim them towards their respective pins.

- Solder ‘Em Up:

- Take one of your tinned wires (e.g., the red one).

- Heat the solder-filled cup on the correct pin (Pin 2) with your soldering iron until the solder in the cup becomes molten.

- Quickly insert the tinned end of the red wire into the molten solder.

- Remove the soldering iron and hold the wire steady for a few seconds while the solder cools and solidifies.

- Repeat: Work your way around, soldering the shield wire to Pin 1 and the blue (or other color) wire to Pin 3.

- Be patient and try not to overheat the connector or melt the plastic. If your “helping hands” aren’t quite cutting it, Dave sometimes uses angle grip pliers to hold a wire in a tight spot.

Do this for both the male and female connector inserts, ensuring the Pin 1-Shield, Pin 2-Red, Pin 3-Blue configuration is identical on both ends.

Finishing Touches: Assembly and Testing

You’re almost there! Just a few more steps to a fully functional, road-ready cable.

H3: Inspecting Your Solder Joints

Take a close look at your handiwork. You’re looking for shiny, smooth solder joints. If they look dull, grey, or balled-up, it might indicate a “cold” solder joint or overworked solder, which could lead to a poor or intermittent connection. If you see a suspect joint, it’s best to reheat it and reflow the solder, or even desolder and start that pin again.

Assembling the Connector Housing

- Strain Relief: Grab the plastic (or sometimes metal) strain relief piece. The tapered end usually goes towards the length of the cable. Slide it over the soldered wires. This piece often fits into grooves on the connector insert and is crucial for preventing pulls on the cable from stressing your delicate solder joints.

- Outer Shell: Take the main metal body of the XLR connector. Line up any key or groove on the insert with the corresponding slot in the shell, and slide it on until it seats properly.

- Boot Up: Finally, screw the boot (that you remembered to put on first!) onto the back of the connector shell. Crank it down nice and tight. This clamps the strain relief onto the cable jacket, securing everything.

Repeat for the other end of the cable.

100+ Insanely Detailed Mixing Tutorials

We leave absolutely nothing out, showing you every single step

Don’t Skip the Test!

You’ve built it, now test it.

- Continuity Test: If you have a multimeter or a dedicated cable tester, check for continuity: Pin 1 on one end should connect only to Pin 1 on the other, Pin 2 to Pin 2, and Pin 3 to Pin 3. Also check for shorts between pins (e.g., Pin 1 shouldn’t connect to Pin 2).

- The Real-Deal Audio Test: As Dave wisely points out, a cable can pass a continuity test but still sound bad or be noisy if there’s a dodgy connection. The ultimate test is to plug it in and pass audio through it. A bad cable can sabotage even the best mic placement for recording metal vocals, so listen for hum, crackles, or a weak/thin signal.

Why Bother DIYing Cables? The Nail The Mix Angle

So, you’ve successfully soldered your own XLR cable. Feels good, right? You’ve saved some cash, you’ve got a high-quality cable made with components you chose, and you’ve gained a valuable skill. This hands-on understanding of how your signal gets from A to B is invaluable. A clean, reliable signal path is the foundation of any great recording or mix. It’s a foundational skill, just as crucial as learning the proper studio speaker setup to ensure you’re hearing that signal accurately.

Building your own cables gives you a real hands-on appreciation for the signal chain. It’s that kind of deep, practical understanding that we champion at Nail The Mix. When you see world-class producers—guys who live and breathe audio—break down their entire process, you’re not just learning button-pushes; you’re learning the why behind every decision. It’s the difference between guessing and knowing exactly how Jens Bogren records metal guitars to get that crushing, clear sound at the source.

If you’re ready to apply that same dedication to understanding every part of your production and mixing workflow, come see what we’re all about. Get those tools cleaned up, plug in your new cable, and take your mixes from “pretty good” to “pro-level” with Nail The Mix.

Get a new set of multi-tracks every month from a world-class artist, a livestream with the producer who mixed it, 100+ tutorials, our exclusive plugins and more

Get Started for $1